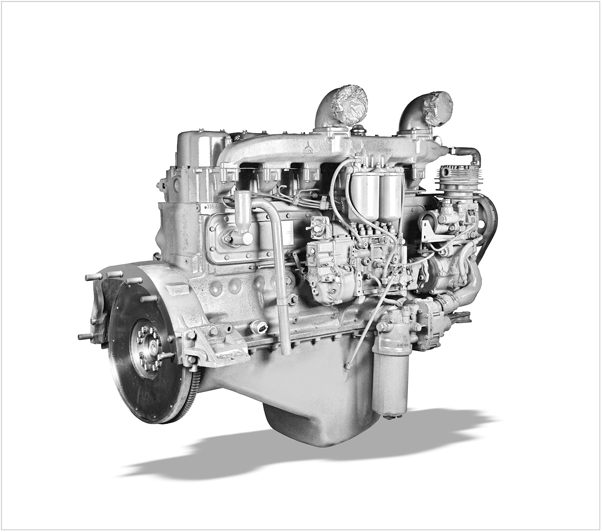

Introducing OM 355 Euro2 Engine

Cylinder block

Cylinder head

The cylinder head is made of cast iron and is separate for each cylinder. The intake manifold and the cylinder head cover are all made of lightweight cast materials.

Crankshaft

The crankshaft is made of one-piece alloy steel by forging method and with very precise machining. The crankshaft of this engine is held in 7 points by three-layer bearings, with steel backs (with a polished bearing in the middle). Also, the crankshaft is balanced by special weights.

Connecting rod

Camshaft

Piston

Valve

The valves are put to work by a combination of bracket, push rod, and rocking arms. Cast iron guide bushings and heat-resistant valve seat rings guarantee a long service life and maintenance period.

Sprinkler system

To use the fuel correctly, the direct injection method is used. The injection system includes a linear pump, fuel pump, fuel filter, multi-hole injector and an automatic injection timer.

Lubrication under pressure

Lubrication operation by means of a gear type oil pump that passes all the oil through the filter and feeds the crankshaft, camshaft, connecting rod, bearing and rocking arms. In this way, the injector pump, governor and air pump are connected to the engine lubrication system. In this system, safety valves are responsible for reducing excess pressure.

Cooling system

By using a centrifugal pump, depending on the application of the engine, air-to-water or water-to-water radiators can be used. The water temperature can be controlled by using a thermostat.

Application

This engine can be used as a reliable source in industrial and commercial equipment, construction, agriculture, commercial vans, as well as a power generator source for all types of sea boats. According to the customer's request, this engine can be used for different purposes by being equipped with special tools.

Technical Specifications of OM 355 Euro2 Engine

| نوع سیلندر | Inline/Vertical | Cylinders type | ||

| تعداد سیلندر | 6 | Cylinders | ||

| قطر سیلندر (میلیمتر) | 128 mm | Cylinder Bore | ||

| کورس پیستون | 150 mm | Stroke | ||

| حجم موتور (لیتر) | 11.58 Lit | Total piston displacement | ||

| نسبت تراکم | 16.82:1 | Compression Ratio | ||

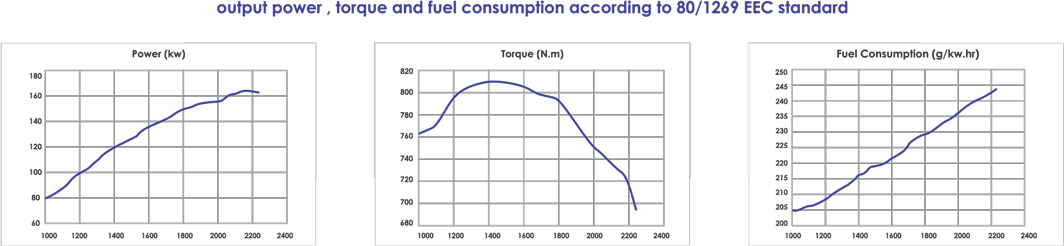

| حداکثر قدرت خروجی (کیلووات) | 166 Kw @ 2200 rpm | Max output (Kw) | ||

| حداکثر گشتاور(نیتوتن/متر) | 820 N.m @ 1400 rpm | Max torque (N-m) | ||

| وزن موتور خشک(کیلوگرم) | 880 Kg | Engine dry weight (kg) | ||

| کنترل موتور | Mechanical | Engine control | ||

| موقعیت نازل | Vertical | Nozzle position | ||

| سرعت متوسط پیستون | 11.36 ms @ 2200 rpm | Mean piston speed | ||

| فشار متوسط موثر | 8.89 bar @ 1400 rpm | Mean effective pressure | ||

| جهت چرخش(خلاف عقربه هاب ساعت) | c.c.w | Rotation | ||

| ظرفیت سیال خنک کننده | 28 Lit | Cooling water capacity | ||

| حداکثر ظرفیت روغن کارتر(اتوبوس/کامیون) | 30/18 Lit | Max lubrication oil capacity (Bus/Truck) | ||

| حداقل مصرف سوخت | 203 gr/kw.h | Min. fuel consumption | ||

| سوپاپ دود | 2 | Exhaust valves | ||

| سوپاپ هوا | 2 | Intake valves | ||

| استاندارد آلایندگی با گوگرد کمتر از 0.05 | EURO II | Emission standard | ||

| سیستم ترمز موتور | No | Engine break system |